Natural Bridges Solar Power

Plant (A large pioneering project) I have recent clients in PV

power plants as well and offer this expertise to current

clients.

In 1980 solar energy was a very

"hot" item and especially the concept

of solar electricity caught the public imagination. (Today

it is even hotter however!) The idea

of building a large demonstration plant in an area which had no

conventional power lines feeding it was appealing to DOE and so they

chose the Natural Bridges National Monument in South Eastern Utah as a

demonstration site 40 miles from the nearest power line as shown in the

Winter scene to the left.

In 1980 solar energy was a very

"hot" item and especially the concept

of solar electricity caught the public imagination. (Today

it is even hotter however!) The idea

of building a large demonstration plant in an area which had no

conventional power lines feeding it was appealing to DOE and so they

chose the Natural Bridges National Monument in South Eastern Utah as a

demonstration site 40 miles from the nearest power line as shown in the

Winter scene to the left.The round park headquarters, other buildings in the area, and a deep well were currently using diesel generators for power and it was decided to construct a 100 kW photo voltaic power plant to essentially take over the load. The diesels would still be used for backup and occasionally for other purposes as well. DOE contracted with MIT Lincoln Labs in Massachusetts to request proposals from contractors to construct the plant. I was working at the time for the engineering firm of Ford Bacon & Davis as manager of their solar activities as I had just designed the solar energy systems for the first solar home in Utah and the first solar subdivision in the state.

No one had ever constructed a photo voltaic plant this size before (although today's plants are up to more than 100 times larger) and there were many unknown factors to consider. For example, how do you control a power source which cannot be turned off when the sun is shining, requiring some parts to be replaced with the power on? How long do batteries last in this sort of use? There were many other problems to address. I wrote the proposal for my company and presented it against the strong proposals of extremely well known companies. We were awarded the contract which was the largest contract the Utah office had received to that point and my position was to take care of all "strange" parts of the project as the co project engineer and make sure the system was reliable with a design unknown for sure at the start, but still to be built within the allowable budget and on time. It was a GREAT project because we didn't know for certain if it would work when we started, but of course by virtue of all we could do, it must work on time, and within budget! Only creative people could make that happen! (And we did!)

The solar array was to use solar panels worth

$1.5 million in 1980 dollars, and test three manufacturers

arrays. These arrays were to be protected with lightning rods as

shown in the photo and the system would be designed to test

the longevity of the solar panels among other requirements. It

would

be necessary to have 100 kW of power produced and to provide a system

to

safely charge the batteries and operate a 50 kW inverter to supply AC

power.

The system ultimately operated over ten years before there was

degradation

in some of the solar panels and it was shut down for a time due to lack

of

funding. It has since been refurbished and began operation once

again in 1992 and is operating today (2009)

The solar array was to use solar panels worth

$1.5 million in 1980 dollars, and test three manufacturers

arrays. These arrays were to be protected with lightning rods as

shown in the photo and the system would be designed to test

the longevity of the solar panels among other requirements. It

would

be necessary to have 100 kW of power produced and to provide a system

to

safely charge the batteries and operate a 50 kW inverter to supply AC

power.

The system ultimately operated over ten years before there was

degradation

in some of the solar panels and it was shut down for a time due to lack

of

funding. It has since been refurbished and began operation once

again in 1992 and is operating today (2009) The battery was composed of industrial lift truck

batteries and was designed to be broken into individual cells for

maintenance as can be seen from the large connectors hanging from the

batteries. The building housing the batteries was separated into two

rooms with the batteries in a room with a lightly constructed outer

wall and a concrete inner wall so that in the event of an

explosion from hydrogen gas, the outer wall would blow out and the

inner wall

would be undamaged. Considerable insulation was used to keep the

battery

room both warm in the winter and cool in the summer to lengthen the

battery

life. (Original batteries lasted ten years)

The battery was composed of industrial lift truck

batteries and was designed to be broken into individual cells for

maintenance as can be seen from the large connectors hanging from the

batteries. The building housing the batteries was separated into two

rooms with the batteries in a room with a lightly constructed outer

wall and a concrete inner wall so that in the event of an

explosion from hydrogen gas, the outer wall would blow out and the

inner wall

would be undamaged. Considerable insulation was used to keep the

battery

room both warm in the winter and cool in the summer to lengthen the

battery

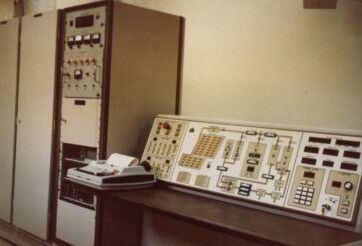

life. (Original batteries lasted ten years) The control room was designed

to not only control the facility, but to serve as an excellent

demonstration of what a PV plant much larger than Natural Bridges might

require in a control system. I designed the control

panel, made a cardboard mockup of it and took it to MIT Lincoln Labs

for evaluation with all controls, meters, and appropriate color schemes

etc.

The intent of the mockup was to make sure that all necessary

functions

were taken care of and that it made a good demonstration display for

photovoltaics.

I recommend this approach for other projects as well.

The control room was designed

to not only control the facility, but to serve as an excellent

demonstration of what a PV plant much larger than Natural Bridges might

require in a control system. I designed the control

panel, made a cardboard mockup of it and took it to MIT Lincoln Labs

for evaluation with all controls, meters, and appropriate color schemes

etc.

The intent of the mockup was to make sure that all necessary

functions

were taken care of and that it made a good demonstration display for

photovoltaics.

I recommend this approach for other projects as well.The innovative safety features "broke" the battery into sections, shut down the inverter, and disconnected the PV array instantly when the large red button at the upper left of the control panel was pushed.

Natural Bridges was another wonderful project where I could truly think "outside the box" and find answers to problems which had never been addressed before. In a way, it is like being the first on top of an unclimbed mountain when you have gone where no one has been before.